Six major factors that need to be considered in the structural design of lithium battery pack PACK

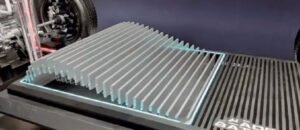

1. Lithium battery pack structure PACK design involves many aspects: such as mechanical structure design, which must consider strength, earthquake resistance, heat dissipation/heating, waterproofing, dustproof, etc.; electrical design, safety regulations, EMC safety regulations, etc. must be considered; and The design of the lithium battery management system must be considered, including overshoot, over-discharge, over-temperature, detection accuracy, battery balance, etc. To ensure the safety and reliability of the battery, it must be reasonably designed and verified by the market.

2. Factors to be considered in the structural design of power lithium battery pack PACK

a. Waterproof, the waterproof grade reaches IP68;

b. Maintain the balance of air pressure inside and outside the lithium battery pack. Because the temperature of the battery pack will change during the charging and discharging process, the air pressure in the battery pack will change. The PUW explosion-proof valve is breathable and water-proof, so it can maintain the air pressure in the pack at all times. Like the outside world;

c. Explosion-proof. Once the lithium battery pack experiences thermal runaway, the air pressure in the battery pack increases sharply. At this time, the battery pack is in danger of exploding, so the PUW explosion-proof valve becomes a breakthrough and can quickly release the pressure in time;

3. In the combination of PACK lithium battery packs, in addition to the control of the safety, reliability and protection level of the battery pack, in terms of cooling and heating, special attention must be paid to the battery connection method and the accuracy of BMS measurement must be considered. This problem is common. , ignoring the impact of voltage drop on the test, thereby affecting the balancing ability of the battery pack.

4. Waterproofing and earthquake resistance are both important in the lithium battery pack PACK structure. Speaking of which, the battery PACK is actually a complex. It involves many aspects, but it would be great if the details can be done well;

5. Integration of lithium battery PACK structural design: After the individual modules are PACKed, they must be connected in series to form a battery pack. At this time, the serial connectionability of each other should be considered to meet the fast and safe series interface form;

6. Internal insulation design issues in battery PACK structure design: The insulation problem of the positive and negative electrodes has been taken into consideration when designing the battery structure, but the uncertain factors of the vehicle battery are too complicated, so it must be designed separately during the PACK battery design process. Predetermined insulation conditions ensure that the battery remains safe and effective in various complex environments such as impact, vibration, and moisture.