As the world pays increasing attention to renewable energy and electric vehicles, battery technology, as a core component of electric vehicles, has also received more and more attention. Among many battery technologies, blade batteries have become the focus of the industry with their unique design and excellent performance. This article will deeply explore the principles, characteristics and application prospects of blade batteries in the field of electric vehicles.

1. Introduction to blade battery

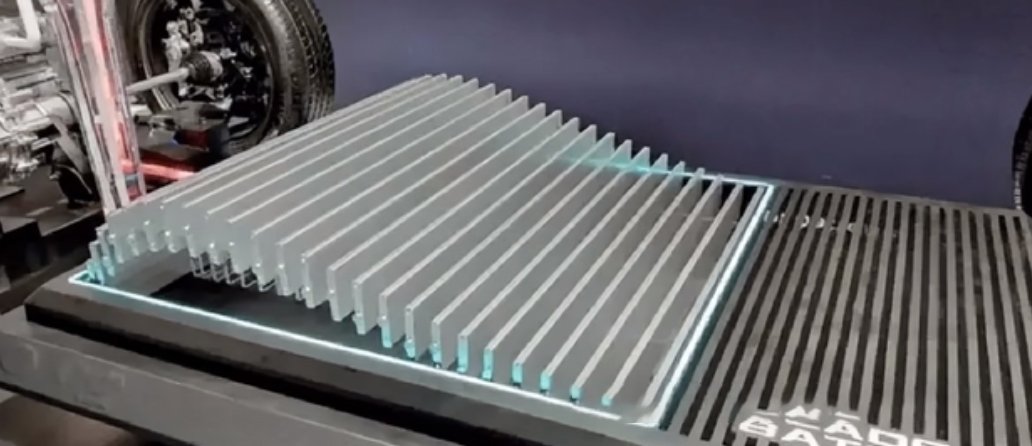

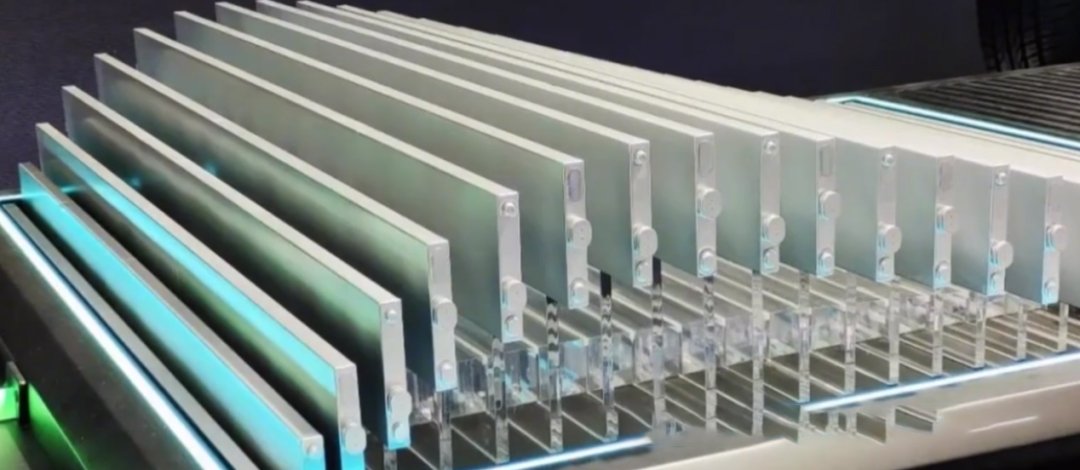

Blade battery is a lithium-ion battery made of lithium iron phosphate material. What makes it unique is the shape and size of the battery, as well as its production process. Blade batteries are shaped like a blade, hence the name. This design allows the battery to be directly embedded into the battery pack, eliminating the need for traditional battery modules, thus improving the energy density and structural strength of the battery pack.

2. Working principle of blade battery

Blade batteries work similarly to traditional lithium-ion batteries. When charging, lithium ions start from the positive electrode and move to the negative electrode through the electrolyte, releasing electrons at the same time; when discharging, the process is reversed. The special design of the blade battery allows these lithium ions to move faster, thereby improving the charging and discharging speed and efficiency of the battery.

3. Characteristics of blade batteries

1. High energy density: Due to the use of lithium iron phosphate material, the blade battery has a higher energy density, which means that under the same weight, the blade battery can provide a longer cruising range.

2. High safety: Lithium iron phosphate material has high thermal stability and chemical stability, so the blade battery is not prone to fire or explosion under abnormal conditions such as high temperature or short circuit.

3. Long life: The lithium iron phosphate material has a long cycle life, which gives the blade battery a long service life. In addition, due to the design of the blade battery, the amount of electrolyte is reduced, which also reduces the loss of the battery.

4. Easy to maintain: The modular design of the blade battery makes it easier to maintain. If there is a problem with one module, it can be replaced individually without having to replace the entire battery pack.

5. Environmentally friendly: Lithium iron phosphate materials have less impact on the environment during the production process and can be recycled and reused after use, which is in line with the concept of green environmental protection.

3. Advantages and disadvantages of blade batteries

Blade batteries have a series of advantages and disadvantages. The advantages and disadvantages of blade batteries will be introduced below.

(1) Advantages

1. High safety: The blade battery uses lithium iron phosphate material, which is not easy to catch fire or explode at high temperatures, so it is highly safe.

2. Long life: Due to the high stability of the lithium iron phosphate material, the life of the blade battery is relatively long, usually more than 10 years.

3. Low maintenance cost: The blade battery has a long life and relatively low maintenance cost because it has a simple structure and is not prone to failure.

4. Fast charging: Blade batteries charge quickly and can usually be fully charged in 1-2 hours, which is much faster than traditional lead-acid batteries.

5. Environmental protection: Lithium iron phosphate material is environmentally friendly, does not produce harmful substances, and meets environmental protection requirements.

(2) Disadvantages

1. Low energy density: Compared with traditional lithium batteries, lithium iron phosphate batteries have a lower energy density, which means that the same amount of electricity requires more battery weight or volume. This may increase the weight and bulk of the vehicle, which may affect the vehicle’s range and performance.

2. Higher cost: The material cost and manufacturing cost of lithium iron phosphate batteries are relatively high, so the overall price is also relatively high. This may make the price of electric vehicles using lithium iron phosphate batteries relatively high, which is not conducive to market promotion.

3. Poor low-temperature performance: Lithium iron phosphate batteries have poor performance in low-temperature environments, and their capacity and discharge rate will be affected. This may limit the use of electric vehicles in colder regions.

4. Limited recharge times: Although the blade battery has a long life, its recharge times are limited. Once a battery reaches its charge limit, it needs to be replaced with a new one. Therefore, users need to pay attention to controlling the number of charging times to extend the service life of the battery.

5. High requirements for charging facilities: Since blade batteries charge quickly, corresponding charging facilities are needed to meet their charging needs. This may increase the construction and maintenance costs of charging facilities.

In summary, blade batteries have the advantages of high safety and long life, but they also have shortcomings such as low energy density, high cost, poor low-temperature performance, limited charging times, and high requirements for charging facilities. Therefore, when choosing to use blade batteries, comprehensive considerations need to be made based on specific application scenarios and needs.