Lithium-ion battery pack hairline cracks are tiny cracks that appear inside or outside the battery pack. These cracks may cause battery performance to degrade or even cause battery failure. In response to such problems, let’s discuss the causes and preventive measures of fine cracks in lithium-ion battery packs.

一. Causes of fine cracks in lithium-ion battery packs

1. Mechanical stress: The battery pack will be affected by mechanical stress during charging and discharging. If the battery pack is not designed properly or is used in a harsh environment, mechanical stress may cause the formation of fine cracks in the battery pack.

2. Thermal stress: Lithium-ion battery packs generate heat during charging and discharging. If the battery pack does not dissipate heat well or if the charge and discharge rate is too high, thermal stress may cause the formation of fine cracks.

3. Uneven expansion: The positive and negative electrode materials inside the lithium-ion battery pack will expand and contract during the charging and discharging process. If the positive and negative electrode materials expand and contract unevenly, it may cause fine cracks to form inside the battery pack.

4. Electrolyte leakage: The electrolyte of lithium-ion battery pack is a corrosive liquid. If electrolyte leaks into other parts of the battery pack, it may cause hairline cracks to form.

二. Preventive measures

Understanding the causes of fine cracks, we can take some preventive measures to reduce their occurrence. Here are some common precautions:

1. Optimize battery pack design: Reasonably design the structure and size of the battery pack to reduce the impact of mechanical stress. At the same time, the casing and supporting structure of the battery pack should have sufficient strength and stiffness to avoid the concentration of mechanical stress.

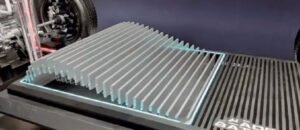

2. Control the charge and discharge rate: Reasonably control the charge and discharge rate of the battery pack to avoid excessive thermal stress caused by excessive rates. In addition, the temperature of the battery pack should be monitored during the charging and discharging process, and heat dissipation measures should be taken promptly to reduce the impact of thermal stress on the battery pack.

3. Optimize positive and negative electrode materials: Research and develop more stable positive and negative electrode materials to reduce uneven expansion and contraction during charging and discharging. In addition, multi-layer composite materials or nanomaterials can be used to improve the performance and stability of positive and negative electrode materials.

4. Strengthen electrolyte sealing: Optimize the sealing structure of the battery pack to ensure that electrolyte does not leak into other parts. At the same time, materials with higher corrosion resistance can be used to make the casing and seals of the battery pack to reduce fine cracks caused by electrolyte leakage.

In addition to the above preventive measures, the production and use of lithium-ion battery packs also require strict quality control, strengthened monitoring and testing, and timely discovery and resolution of potential problems. In addition, battery packs that have developed fine cracks should be stopped in time and repaired or replaced.

To sum up, the causes of fine cracks in lithium-ion battery packs are complex and diverse, and preventive measures need to be comprehensively considered from multiple aspects such as design, materials, and processes. Through reasonable design and optimization, as well as strengthening quality control and monitoring, the occurrence of fine cracks can be effectively reduced and the safety and reliability of lithium-ion battery packs can be improved. ”