Battery sheet process flow:

Fleece (INTEX)→ diffusion (DIFF)→ post-cleaning (edging/PSG removal)→ anti-reflection film

plating (PECVD)→ Screen, sintering (PRINTER)→ Test, sorting (TESTER+SORTER)→ PACKING

1.Fleece

The purpose of velvet is to form a suede surface on the surface of the silicon wafer to reduce the

reflectivity of the battery, and the roughness of the suede can increase the secondary reflection

and change the light path and incident mode. Under normal circumstances, a pyramidal suede

can be obtained by treating single crystal with alkali; Treat polycrystals with acid, and you can get

wormhole shaped irregular suede. The treatment method is mainly different from that of single

polycrystal.

Process flow: fluting tank → washing → alkali washing → washing → pickling → washing

→ blow drying.

Under normal circumstances, silicon is considered to be non-reactive with HF and HNO3 (silicon

surface will be passivated). When present in a system of two mixed acids, the reaction of silicon

with the mixed solution is continuous.

2. Diffusion

Diffusion is the manufacture of the heart for the battery, is the manufacture of P-N junction for

the battery, POCl3 is the current phosphorus diffusion more choice. POCl3 is a l iquid phosphorus

source, and liquid phosphorus source diffusion has the advantages of high production efficiency,

good stability, uniform PN junction and good diffusion layer surface.

POCl3 decomposed into phosphorus pentachloride (PCl5) and phosphorus pentoxide (P2O5)

under the condition of more than 600℃, PCl5 has a corrosive effect on the surface of the silicon

wafer, when there is oxygen O2, PCl5 will decompose into P2O5 and release chlorine gas, so the

diffusion of nitrogen at the same time through a certain flow of oxygen. P2O5 reacts with silicon

at the diffusion temperature to generate silicon dioxide and phosphorus atoms, the generated

P2O5 deposited on the surface of the silicon and silicon continue to react to generate SiO2 and

phosphorus atoms, and form phosphate-silicon glass (PSG) on the surface of the silicon,

phosphorus atoms diffuse to silicon, the preparation of N-type semiconductor.

3. Etching

In the diffusion process, the back-to-back single-sided diffusion method is used, and the side and

back edges of the silicon wafer will inevitably be diffused with phosphorus atoms. When sunlight

hits the front of the P-N junction, the photogenerated electrons collected on the front of the P-N

junction flow to the back of the P-N junction along the phosphorus diffusion area of the edge,

causing a short circuit. The short-circuiting channel is equivalent to reducing the shunt resistance.

The etching process is to remove the phosphorus on the edge of the silicon wafer, avoiding the

short circuit of the P-N junction and resulting in the reduction of the parallel resistance.

Wet etching process: upper wafer → etching tank (H2SO4 HNO3 HF)→ water washing →

alkali tank (KOH)→ water washing →HF tank → water washing → lower wafer

HNO3 reaction oxidizes to SiO2, and HF removes SiO2. The role of the etching alkali tank is to

polish the unmade suede and make the battery smooth; The main solution of alkali tank is KOH;

H2SO4 is used to float the silicon wafers on the assembly line and does not participate in the

reaction.

Dry etching uses plasma to etch thin films. When the gas exists in the form of plasma, on the one

hand, the chemical activity of the gas in the plasma will become relatively strong, and the

suitable gas can make the silicon wafer react more quickly to achieve etching; On the other hand,

the electric field can be used to guide and accelerate the plasma, so that the plasma has a certain

energy. When bombarding the surface of the silicon wafer, the atoms of the silicon wafer material

are knocked out, which can achieve the purpose of using physical energy transfer to achieve

etching.

4.PECVD

Plasma chemical vapor deposition. The reflection loss rate of sunlight on the silicon surface is as

high as about 35%. Antireflection film can improve the absorption of sunlight by the battery, help

to improve the photogenerated current, and then improve the conversion efficiency: on the

other hand, the passivation of hydrogen in the film on the surface of the battery reduces the

surface recombination rate of the emission junction, reduces the dark current, improves the

open circuit voltage, and improves the photoelectric conversion efficiency. H can react with

defects or impurities in silicon, so as to transfer the energy band in the forbidden band to the

valence band or conduction band.

The silicon wafer is coated with a layer of SixNy film by conducting electricity to the graphite boat

under vacuum and at a temperature of 480 degrees Celsius.

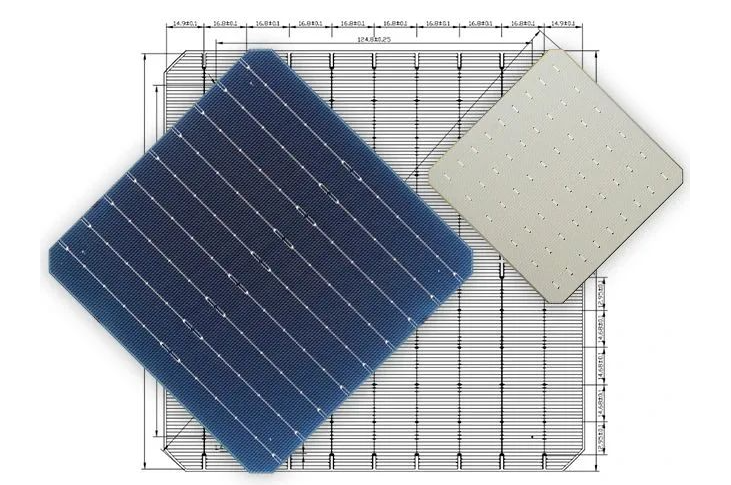

5.Screen printing

In popular terms, it is to collect current for solar cells and manufacture electrodes, the first silver

electrode on the back and the second aluminum back field on the back of the printing and drying;

The printing of the third front silver electrode mainly monitors the wet weight after printing and

the width of the secondary grid line. If the second wet weight is too large, it will not only waste

the paste, but also may not be able to dry fully before entering the high temperature zone, or

even drive out all the organic matter in it so that the entire aluminum paste layer can not be

transformed into metal aluminum, in addition, the wet weight is too large may cause the battery

blade after sintering. If the wet weight is too small, all the aluminum paste will be consumed in

the subsequent sintering process to form a melting area with silicon, and the alloy area is not

suitable for contact as the back metal in terms of transverse conductivity or weldability, and there

may be bad appearance such as bulges. The width of the third grid line is too large, which will

reduce the light area of the battery and reduce the efficiency.

Printing method: physical printing, drying.

6. Sintering

Sintering is the electrode printed on the surface of the battery at high temperature sintering, so

that the electrode and the silicon wafer itself form ohmic contact, improve the open circuit

voltage and filling factor of the battery, so that the contact of the electrode has resistance

characteristics to achieve high conversion efficiency, sintering process can also facilitate the

introduction of PECVD process -H diffusion into the body, can play a good body passivation effect.

Sintering method: high temperature rapid sintering, heating method: infrared heating

Sintering is a set of diffusion, flow and physical and chemical reaction of a comprehensive effect

of a process, the front Ag through SiNH diffusion into silicon but can not reach the P-N surface,

the back Ag, Al diffusion into silicon, because the need to form alloys to a certain temperature,

Ag, Al and Si to form alloys stable and different, you need to set different temperatures to

achieve alloying.