Introduction:

As an important part of lithium batteries, battery wiring harness plays a key role in improving battery performance. Now we will discuss with you the role, design principles and future development trends of lithium battery wiring harnesses.

1. The role of lithium battery wiring harness

Lithium battery wiring harness is a combination of wires that connect battery cells. Its main function is to provide current transmission and battery management system functions. Lithium battery wiring harness plays a vital role in improving battery performance, including the following aspects:

1. Current transmission: The lithium battery harness transmits current from the battery cell to the entire battery pack by connecting the battery cells to ensure the normal operation of the battery pack. At the same time, lithium battery wiring harnesses need to have low resistance and high conductivity to reduce energy loss during current transmission.

2. Temperature control: Lithium batteries generate heat during operation, and the lithium battery wiring harness needs to have good heat dissipation performance to ensure that the temperature of the battery pack is within a safe range. Through reasonable wire harness design and material selection, the heat dissipation effect of the battery pack can be improved and the battery life can be extended.

3. Battery management system support: The lithium battery harness also needs to be connected to the battery management system (BMS) to monitor and manage the battery pack. Through the connection between the lithium battery harness and the BMS, the voltage, temperature, current and other parameters of the battery pack can be monitored in real time to ensure the safety performance of the battery pack.

2. Design principles of lithium battery wiring harness

In order to ensure the performance and safety of lithium battery wiring harness, the following principles need to be followed during design:

1. Low resistance: Choose low-resistance wire materials and reasonable wire harness cross-sectional areas to reduce energy loss during current transmission.

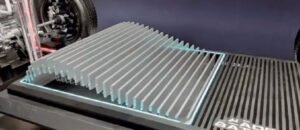

2. Good heat dissipation performance: Choose wire materials with good heat dissipation performance, and rationally design the layout of the wire harness to improve the heat dissipation effect of the battery pack.

3. High temperature resistance: Lithium batteries will generate high temperatures during operation, so the lithium battery wire harness needs to have good high temperature resistance to ensure the stability and safety of the wire harness.

4. Safety and reliability: Lithium battery wire harnesses need to have good insulation properties and corrosion resistance to prevent short circuits and damage to the wire harness during work.

3. The design and production of lithium battery wiring harness need to consider the following aspects:

1. Wire material selection: Choose wire materials with good electrical conductivity and high temperature resistance, such as copper wires or aluminum wires. The cross-sectional area of the wire should be reasonably selected based on the current size and voltage drop requirements.

2. Insulation material selection: Choose insulation materials with good insulation properties and high temperature resistance, such as polyvinyl chloride (PVC), polyethylene (PE) or polytetrafluoroethylene (PTFE). The selection of insulation materials should comply with relevant standards and requirements.

3. Wiring harness layout design: According to the electrical layout and requirements of the equipment, rationally design the wiring harness layout to avoid crossover and interference between wires. At the same time, considering the heat dissipation requirements of lithium batteries, the heat dissipation channels of the wiring harness should be reasonably arranged.

4. Wire harness fixation and protection: The wire harness should be fixed and protected to prevent it from being pulled, squeezed or damaged by external forces during use. Materials such as zip ties, insulating tape, and sleeves can be used to secure and protect.

5. Safety performance test: After the production is completed, the lithium battery wire harness needs to be tested for safety performance, such as resistance test, insulation test, voltage withstand test, etc., to ensure that the safety performance of the wire harness meets the requirements.

In summary, the design and production of lithium battery wire harnesses need to consider factors such as wire materials, insulation materials, wire harness layout, wire harness fixation and protection, and conduct safety performance tests to ensure the quality and safety performance of the wire harness. Only in this way can the normal operation and safety of lithium battery equipment be ensured.

4. Future development trends of lithium battery wiring harnesses

With the rapid development of the electric vehicle market and the continuous improvement of battery performance requirements, the future development trend of lithium battery wiring harnesses will mainly focus on the following aspects:

1. Material innovation: Develop wire materials with higher conductivity and lower resistance to improve the energy transmission efficiency of the battery pack.

2. Improvement in heat dissipation technology: By using new heat dissipation materials and heat dissipation structure design, the heat dissipation effect of the battery pack is improved and the battery life is extended.

3. Intelligent management: Combined with intelligent technology, real-time monitoring and management of lithium battery wiring harnesses can be achieved to improve the safety performance of the battery pack.

4. Wiring harness integration: Integrate more functions into the lithium battery wire harness, such as current sensors, temperature sensors, etc., to simplify the design and management of the battery pack.

5. Conclusion

As an important component of lithium batteries, lithium battery wiring harness plays a key role in improving battery performance. Through reasonable design and material selection, lithium battery wiring harness can improve the energy transmission efficiency, heat dissipation effect and safety performance of the battery pack. In the future, with the continuous innovation and development of technology, lithium battery wiring harness will further improve battery performance and provide more reliable and efficient energy solutions for the development of electric vehicles.