Lithium battery process technology refers to the related processes and technologies used in the production and manufacture of lithium batteries. A lithium battery is a rechargeable battery that uses the movement of lithium ions between the positive and negative electrodes to store and release electrical energy. The development of lithium battery process technology aims to improve the performance, safety and life of lithium batteries to meet the needs of different application fields.

1. Basic knowledge of lithium battery technology

1. The basic structure of a lithium battery: a lithium battery consists of a positive electrode, a negative electrode, an electrolyte and a separator. The positive electrode material is usually a lithium compound, such as lithium manganese oxide, lithium cobalt oxide, or lithium iron phosphate. The negative electrode material is usually graphite. The electrolyte is a mixture of lithium salts and organic solvents. The separator is used to prevent direct contact between the positive and negative electrodes.

2. Preparation process of lithium battery: The preparation process of lithium battery includes the steps of electrode preparation, battery assembly and packaging.

(1) Electrode preparation: The electrode is the core part of the lithium battery, including positive and negative electrodes. The preparation of positive and negative electrodes usually includes the steps of material mixing, coating, drying and pressing. The preparation of positive and negative electrodes needs to control parameters such as material ratio, coating uniformity and drying temperature to ensure the performance and consistency of the electrodes.

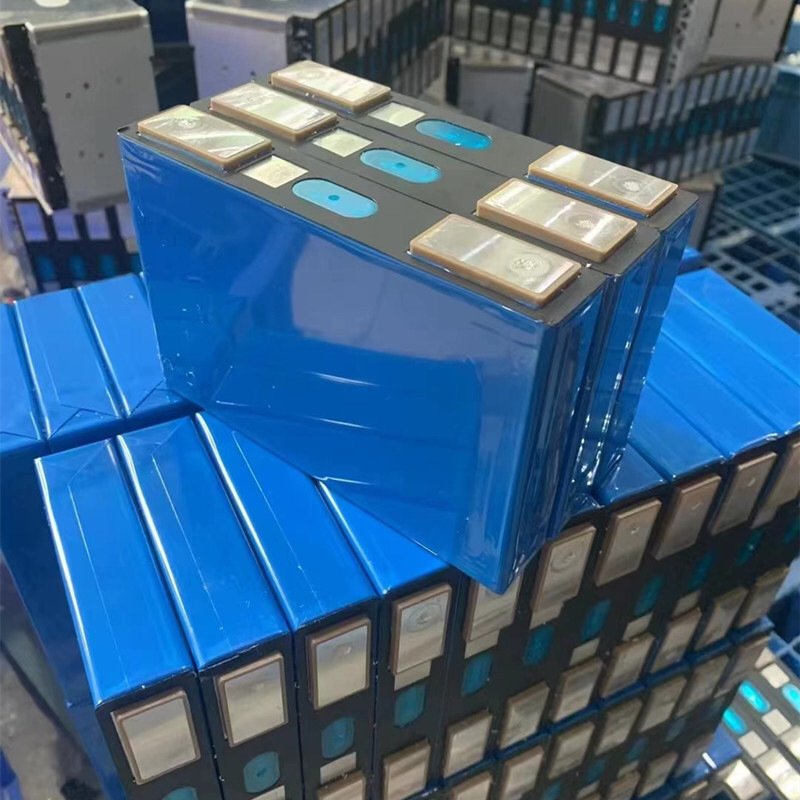

(2) Battery assembly: Battery assembly includes stacking positive electrodes, negative electrodes, and separators in a certain structure to form a battery structure. The symmetry of the electrodes, the tightness of the lamination, and the correct installation of the separator need to be paid attention to during assembly to ensure the performance and safety of the battery.

(3) Packaging: After the battery is assembled, it needs to be packaged to ensure the sealing and safety of the battery. The packaging usually adopts aluminum-plastic composite film or metal casing, and the battery packaging is sealed by heat sealing or welding.

3. Lithium battery testing and quality control: Lithium battery production requires various tests and quality controls to ensure battery performance and consistency. Common tests include battery capacity test, internal resistance test, cycle life test, etc. Quality control includes raw material inspection, process parameter control and finished product inspection, etc.

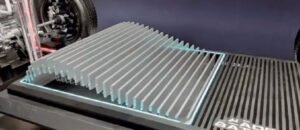

4. Safety considerations for lithium batteries: Due to the high energy density and chemical reactivity of lithium batteries, safety is a special concern when manufacturing and using lithium batteries. In order to improve the safety of lithium batteries, a series of measures need to be taken, such as designing safety valves, using fireproof materials, and controlling battery temperature.

2. Common lithium battery technology

1. Positive and negative electrode materials: The positive electrode of lithium batteries usually uses lithium compounds, such as lithium manganese oxide (LiMn2O4), lithium cobalt oxide (LiCoO2) and lithium iron phosphate (LiFePO4). The negative electrode usually uses graphite or silicon. Different material combinations can affect the energy density, cycle life, and safety performance of batteries.

2. Electrolyte: The transmission of lithium ions in the battery needs to pass through the electrolyte. Commonly used electrolytes are composed of lithium salts dissolved in organic solvents. Optimizing the composition of the electrolyte can increase the conductivity and charge-discharge efficiency of the battery, as well as improve the safety of the battery.

3. Design of the battery case: The battery case is the protective casing of the lithium battery, and it needs to have good sealing and impact resistance. Different application scenarios may require different materials and designs to suit specific environmental conditions.

4. Battery management system (BMS): BMS is a system used to monitor and manage lithium batteries, including the monitoring and control of battery voltage, temperature, charge and discharge current and other parameters. BMS can improve the safety of the battery, ensure that the battery is operating within the proper operating range, and extend the life of the battery.

5. Manufacturing process: The manufacturing of lithium batteries requires a series of process steps, including electrode film coating, battery assembly, charge and discharge testing, etc. Optimization of the manufacturing process can improve battery consistency and reliability.

The continuous development and innovation of lithium battery technology is of great significance to promote the performance improvement, cost reduction and application expansion of lithium batteries.

If you have more needs, please contact us!

https://wa.me/message/CAA3L465O4QJM1