Lithium batteries are mainly composed of positive electrode materials, negative electrode materials, separators and electrolytes. The performance of the positive electrode materials directly affects various performance indicators of lithium batteries. Therefore, lithium battery positive electrode materials occupy a core position in lithium batteries, and positive electrode materials account for a large proportion. (The mass ratio of positive and negative electrode materials is 3:1~4:1), because the performance of the positive electrode material directly affects the performance of the lithium battery, and its cost also directly determines the cost of the battery.

1. Cathode material

The cathode material of lithium batteries is an important component of lithium-ion batteries, and its performance directly affects key parameters such as energy density, charge and discharge performance, and cycle life of the battery. Common cathode materials are:

1. Lithium cobalt oxide (LiCoO2): Lithium cobalt oxide is the cathode material of the first generation of commercial lithium-ion batteries, with high operating voltage and good cycle stability. However, cobalt resources are limited, the price is high, and the thermal stability is poor.

2. Lithium manganate (LiMn2O4): Lithium manganate is a low-cost, high-safety cathode material, especially suitable for large-capacity lithium-ion batteries. However, its cycle performance and high temperature performance are relatively poor, and manganese dissolution is prone to occur at high temperatures.

3. Lithium nickelate (LiNiO2): Lithium nickelate has high energy density, good cycle performance and thermal stability, but there is a problem of nickel ion dissolution, which may cause internal short circuit of the battery.

4. Lithium iron phosphate (LiFePO4): Lithium iron phosphate is a new cathode material with the advantages of high safety, long life, and high thermal stability. However, its energy density is relatively low, which limits its application in high-power applications.

5. Lithium titanate (Li4Ti5O12): Lithium titanate has high thermal stability, fast charge and discharge performance and high safety, and is especially suitable for electric vehicles and energy storage systems. But its energy density is relatively low.

2. Negative material

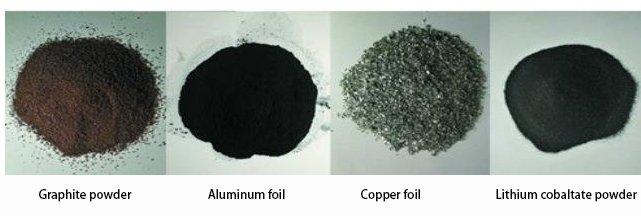

The negative electrode is made by mixing the negative active material carbon material or non-carbon material, adhesive and additives to make a paste-like adhesive, which is evenly applied on both sides of the copper foil, dried and rolled. The negative electrode material is the main body of lithium-ion batteries that stores lithium, allowing lithium ions to be embedded and extracted during the charge and discharge process. When a lithium-ion battery is charged, the lithium atoms in the positive electrode are ionized into lithium ions and electrons, and the lithium ions move to the negative electrode and combine with the electrons to form lithium atoms. During discharge, lithium atoms are ionized from the surface of the negative electrode in the graphite crystal into lithium ions and electrons, and are synthesized into lithium atoms at the positive electrode. The anode material mainly affects the initial efficiency and cycle performance of the lithium-ion battery. The performance of the anode material also directly affects the performance of the lithium-ion battery. The anode material accounts for about 15% of the total cost of the lithium-ion battery. The types of negative electrode materials include carbon negative electrodes and non-carbon negative electrodes. Common negative electrode materials are:

1. Graphite: Graphite has good electrical conductivity, stable chemical properties and high lithium ion intercalation capacity. It is the most commonly used anode material for commercial lithium-ion batteries. However, graphite has a low lithium insertion capacity, which limits the energy density of lithium-ion batteries.

2. Lithium titanate (Li4Ti5O12): Lithium titanate is a new anode material with high thermal stability, fast charge and discharge performance and high safety. It is especially suitable for electric vehicles and energy storage systems. But its energy density is relatively low.

3. Silicon-based materials: Silicon-based materials have extremely high lithium ion embedding capacity and can theoretically increase the energy density of lithium-ion batteries. However, silicon will undergo volume expansion and contraction during the charge and discharge process, resulting in damage to the electrode structure and degradation of cycle performance.

4. Tin-based materials: Tin-based materials have high lithium ion insertion capacity and excellent cycle performance. They are a potential new anode material. However, the chemical properties of tin are active and can easily react with the electrolyte, resulting in a decrease in battery performance.

Generally speaking, the positive and negative electrode materials of lithium batteries have an important impact on the performance and safety of the battery. With the development of science and technology and the changing application requirements, the research and development and application of new positive and negative electrode materials are also constantly advancing.