During the use of lithium batteries, many users have discovered such a problem when using lithium batteries: the capacity of lithium batteries will become lower in winter. This article will discuss in detail the reasons why the capacity of lithium batteries becomes low in winter and propose corresponding solutions.

1. Reasons why the capacity of lithium batteries becomes lower in winter

1. The viscosity of the electrolyte increases

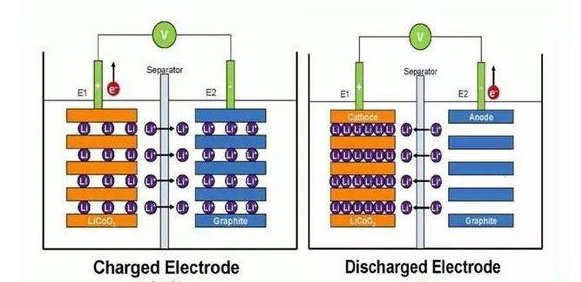

The electrolyte of lithium batteries is composed of carbonate organic solvents and lithium hexafluorophosphate solute. Under low temperature conditions, the viscosity of the electrolyte increases, and the diffusion rate of lithium ions in the electrolyte slows down, resulting in a decrease in battery performance.

2. The compatibility between the electrolyte, the negative electrode, and the separator becomes worse: In a low-temperature environment, the compatibility between the electrolyte, the negative electrode, and the separator becomes worse, which will affect the transmission of lithium ions and the performance of the battery.

2. Reduced reversibility of active substances

Under low temperature conditions, the reversibility of the active material of lithium batteries is reduced, which means that the efficiency of the battery during charging and discharging is reduced, resulting in a reduction in battery capacity.

3. The internal diffusion system of the active material is reduced: In low temperature environments, the internal diffusion system of the active material of lithium-ion batteries is reduced, and the charge transfer resistance (Rct) increases significantly. This means that the resistance to the movement of lithium ions inside the active material increases, resulting in a reduction in the battery’s capacity.

4. The resistance of the battery separator increases

The separator of lithium batteries will become more rigid under low temperature conditions, causing the resistance of lithium ions to pass through the separator, which will also affect the performance of the battery.

5. Thermal stability of battery components decreases

In low-temperature environments, the thermal stability of battery components decreases, and the internal temperature of the battery is more likely to rise. Excessively high temperatures can negatively impact battery performance.

6. Lithium is precipitated from the negative electrode: In low-temperature environments, lithium is seriously precipitated from the negative electrode of lithium-ion batteries, and the precipitated metallic lithium reacts with the electrolyte, and the product deposition causes the thickness of the solid electrolyte interface (SEI) to increase. This affects the transport of lithium ions and the performance of the battery.

7. The increase in lithium ion dispersion impedance of lithium-ion batteries at low temperatures: This is one of the important factors affecting the low-temperature performance of lithium-ion batteries. At low temperatures, the dispersion resistance of lithium ions in the electrolyte increases, causing the transmission speed of lithium ions to slow down, thus affecting the capacity of the battery.

2. Solutions

1. Improve the low-temperature performance of the electrolyte

By improving the formula and composition of the electrolyte and reducing its viscosity under low temperature conditions, the diffusion rate of lithium ions in the electrolyte can be increased, thereby improving the performance of the battery. For example, new organic solvents can be used or additives can be used to reduce the viscosity of the electrolyte.

2. Optimize the structure and composition of active substances

By changing the structure and composition of the active material, its reversibility under low temperature conditions can be improved. For example, new types of active substance coatings can be used or the size and shape of the active substance particles can be changed.

3. Improve the material and structure of the diaphragm

The use of new separator materials and structures can improve its softness and breathability under low temperature conditions, reduce the resistance of lithium ions passing through the separator, and thereby improve battery performance. For example, porous membranes or composite membranes may be used.

4. Enhance battery thermal management

By strengthening the thermal management of the battery, the internal temperature of the battery can be kept stable and the impact of overheating on battery performance can be avoided. For example, a heat dissipation device can be added to the battery pack or the heat dissipation design of the battery pack can be optimized. In addition, the operating temperature of the battery can also be adjusted through intelligent charging and discharging control strategies. For example, the size and time of the current are controlled during the charging process to prevent the battery temperature from being too high; and the work is stopped in a timely manner during the discharging process to lower the battery temperature. These measures can help keep the temperature inside the battery stable and improve battery performance.

5. Add thermal insulation device

Adding a thermal insulation device outside the battery is also an effective solution. The thermal insulation device can reduce the impact of the external environment on the battery and maintain the normal operating temperature of the battery. For example, insulation materials or heating devices can be added to the lithium battery packs of electric vehicles to improve their performance in low-temperature environments.

6. Use low-temperature-resistant electrolyte: By choosing an electrolyte with a lower freezing point and higher conductivity, you can maintain good working performance in low-temperature environments. At the same time, some additives can be added, such as lithium salts, surfactants, etc., to improve the physical and chemical properties of the electrolyte and improve its performance in low-temperature environments.

7. Optimize electrode materials: Choosing electrode materials with better low-temperature performance, such as using nanomaterials, composite materials, etc., can improve the performance of electrodes in low-temperature environments. At the same time, surface treatment and doping of electrode materials can be used to improve their compatibility with the electrolyte and reduce the interface impedance.

8. Control the charge and discharge status of lithium-ion batteries: In low-temperature environments, the charge and discharge status of lithium-ion batteries can be controlled by reducing the charge and discharge current to maintain the normal operating temperature of the battery. At the same time, intelligent charging and discharging control strategies can be used to adjust the size and time of the current according to the ambient temperature and battery status to avoid overheating or overcooling of the battery.

9. Enhance the insulation effect of the battery: Reduce the impact of the external environment on the battery and maintain the normal operating temperature of the battery by adding insulation materials and setting up insulation layers. At the same time, some active heating measures can be taken, such as installing heating films, heating rods, etc., to increase the temperature of the battery.

10. Improve the structural design of lithium-ion batteries: By optimizing the structural design of lithium-ion batteries, the diffusion resistance inside the active material is reduced and the transmission speed of lithium ions is increased. For example, more compact electrode structure design, reduced electrode thickness, increased electrode porosity, etc. can be used to improve the transport performance of lithium ions inside the active material.

3. Conclusion

To sum up, the reasons for the low capacity of lithium batteries in winter mainly include increased electrolyte viscosity, reduced reversibility of active materials, increased separator resistance, and reduced thermal stability of battery components. In order to solve this problem, a variety of measures can be taken, including improving the low-temperature performance of the electrolyte, optimizing the structure and composition of the active material, improving the material and structure of the separator, strengthening the thermal management of the battery, and adding insulation devices. These measures can improve the performance and capacity of lithium batteries in low-temperature environments and meet user needs.