What is TOPCon battery?

TOPCon battery is a kind of photovoltaic crystalline silicon battery, in recent years, due to its high conversion efficiency, low attenuation performance, high mass production cost performance and other obvious advantages, gradually adopted by the industry enterprises.

The theoretical limit efficiency of TOPCon cells is as high as 28.7%, which is the closest technology to the theoretical limit efficiency of crystalline silicon solar cells (29.43%), much higher than that of PERC (24.5%), and has very large research and development potential.

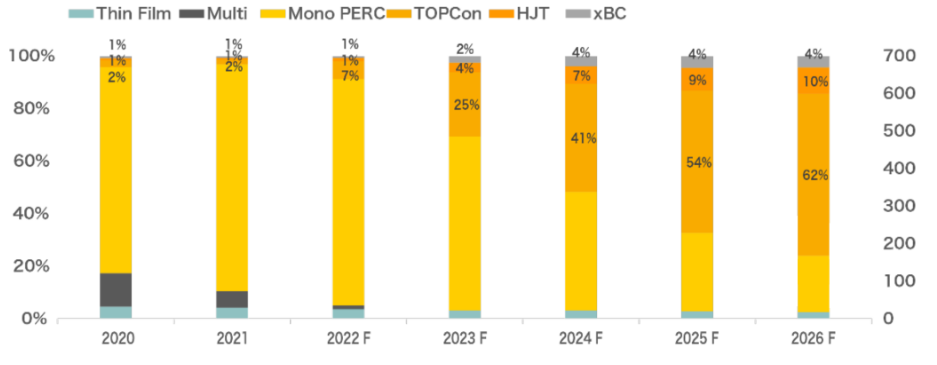

2023 as the year of TOPCon technology outbreak, the market share is expected to account for more than 25%.

In terms of time, TOPCon battery technology was first proposed by the Fraunhofer Institute for Solar Energy in Germany in 2014 as a new type of passivated contact solar cell.

From the perspective of structure, TOPCon is a kind of Tunnel Oxide Passivated Contact solar cell technology based on the principle of selective carrier. Its cell structure is N-type silicon substrate cell. A layer of ultra-thin silicon oxide is prepared on the back of the cell, and then a thin layer of doped silicon is deposited. The two together form a passivation contact structure, which effectively reduces the surface composite and metal contact composite.

TOPCon Battery Technology

Compared with the single crystal PERC process, the TOPCon battery production process needs 2 to 3 more steps, namely, the deposition of the tunnelled oxide layer (ultra-thin SiO2, 1 to 2nm), the deposition of the intrinsic polycrystalline silicon passivation layer (60 to 100nm), and phosphorus injection.

TOPCon main processes and functions

1. Cleaning and fleece

① Purpose

The edge of the silicon wafer is damaged after cutting, the lattice structure of the silicon is damaged, and the surface composite is serious. The main purpose of cleaning and milling is to remove the surface damage and form the surface pyramid light trapping structure. The light shining on the surface of the silicon wafer is refracted several times to reduce the reflectivity.

2. Boron diffusion process

① Purpose

The main function is to prepare the PN junction, which requires high temperature and longer time for diffusion due to the low solid solubility of boron in silicon. At the same time, the choice of diffusion source will also have an impact on the production process, the corrosion of chloride is strong, the viscosity of bromide is large, the cleaning process is cumbersome, and the operation and maintenance cost is increased.

Boron diffusion is usually done at higher temperatures – more than 1000 ° C, and the cycle time for boron diffusion is 150min compared to the 102min cycle required for phosphorus diffusion.

Gaseous HCl and H2O generated by the reaction in the furnace tube will be uniformly distributed in the furnace tube under the carry of N2. H2O will react with BBr3 and O2 to form B2O3 to form gaseous HBO2. HBO2 will decompose at high temperature to form B2O3, which can realize the uniform distribution of B2O3 on the surface of the solar cell.

On the other hand, H2O will also react with B2O3 deposited in the furnace tube, which avoids the deposition of B2O3 on the wall of the diffusion furnace tube, prolongs the service life of the quartz device, and increases the effective boron source.

HCl can also react with metal impurities on the surface of the solar cell and in the furnace tube to generate gaseous metal chloride, which is discharged with the tail gas to avoid the diffusion of metal impurities into the inside of the solar cell during the high temperature process.

3. SE laser doping process

① Purpose

The selective emitter is formed, which is mainly doped in high concentration at and near the contact point between the metal gate line and the silicon wafer to reduce the contact resistance between the front metal electrode and the silicon wafer. However, low concentration doping in the region outside the electrode can reduce the recombination of the diffusion layer. Through the optimization of the emitter, the output current and voltage of the solar cell are increased, so as to increase the photoelectric conversion efficiency.

TOPCon+SE battery structure

② The process of laser in TOPCon process

PERC SE is doped with phosphorus, while TOPCon SE is doped with boron. Due to the different separation coefficients of boron and phosphorus, phosphorus is more easily diffused from silica to silicon, while boron is more easily diffused from silicon to silicon, requiring greater energy to promote doping, and the laser energy is too large and easy to cause damage to silicon, so it is more difficult to doping boron into silicon.

Compared with traditional boron diffusion, TOPCon battery overlay SE technology can theoretically achieve an efficiency increase of 0.5%, and in actual mass production can achieve an efficiency increase of 0.2 to 0.4%.

4. Etching process

① Purpose

The main function of etching is to remove BSG and back knots. The diffusion process will form a diffusion layer on the surface and surrounding of the silicon wafer, and the peripheral diffusion layer is easy to form a short circuit, and the surface diffusion layer will affect the subsequent passivation, so it needs to be removed. At present, etching is mainly carried out by the wet method, which first removes the back and peripheral diffusion layer in the chain device, and then treats the front.

5. Preparation of tunneling oxide layer and polysilicon layer

① Purpose

A 1-2nm tunneling oxide layer was deposited on the back side, followed by a 60-100nm polysilicon layer to form a passivated structure. TOPCon passivation layer is prepared in many ways, mainly divided into LPCVD, PECVD, PVD routes, etc. At present, LPCVD is the main route, but the plating is serious, and the comprehensive performance of PECVD has strong potential.

6. Prepare the back anti-reflection film

① Purpose

The anti-reflection passivation film is prepared on the back of the cell to increase the absorption of light. At the same time, the hydrogen atom generated during the formation of the SiNx film has a passivation effect on the silicon wafer.

7. Front aluminum plating

① Purpose

A layer of alumina film is deposited on the front of the silicon wafer to form a positive passivation effect together with other film layers.

8. Prepare positive anti-reflection film

① Purpose

The effect of the front anti-reflection film is basically the same as that of the back, in addition, the aluminum oxide film deposited on the front is very thin, which is easy to be destroyed in the production of subsequent battery components, and the front SiNx also has a protective effect on aluminum oxide.

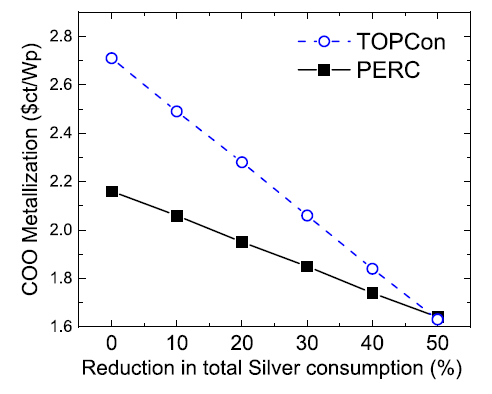

9. Screen printing – laser transfer

At present, in the battery printing process, most of the screen printing is still used.

In the future, in the direction of silver paste consumption of N-type batteries, laser Pattern Transfer Printing technology may have more advantages.

Laser transfer is a new type of non-contact printing technology, which is to coat the required paste on a specific flexible light transmittance material, and use a high-power laser beam to transfer the paste from the flexible light transmittance material to the battery surface to form a grid line and prepare the front and rear electrodes.

10. Sintering

Good ohmic contact is formed by sintering at high temperature.

11. Automatic sorting

The cells with different conversion efficiency are graded.

TOPCon battery advantage

The reason why TOPCon batteries can be adopted by the majority of enterprises is obvious, and its advantages are mainly reflected in the following aspects:

1. High conversion efficiency

TOPCon’s current highest production efficiency is 25.2%, the current mainstream PERC is 23.2%, TOPCon is 2 percentage points higher.

It is expected that by the second half of 2023, TOPCon can reach 26.8%, PERC efficiency is about 23.5%, and the efficiency difference can reach 3.3 percentage points.

2. Low attenuation rate

N-type cell silicon substrate doped with phosphorus, no boron oxygen to form a composite center loss of electron capture, almost no light attenuation.

The first year decay rate of TOPCon components is about 1%(PERC is about 2%), and the average annual decay rate after the first year is about 0.4%(PERC is about 0.45%).

3. Low temperature coefficient

At the component end, the power temperature coefficient of the PERC component is -0.34%/ ° C, while the power temperature coefficient of the TOPCon component is as low as -0.30%/ ° C, which makes the power generation performance of the TOPCon component particularly outstanding in high temperature environments.

4. High double-sided ratio

TOPCon double-sided rate can reach more than 80%, PERC about 70%.

Due to the vast area of large-scale base engineering and high ground reflectivity (usually up to 30%), N-type components with high double-sided rate are used in large-scale base engineering, and the power generation gain is more obvious.

If you have more needs, please contact us.

https://solarpowerxx.en.alibaba.com/