Power-x

Production with passion for technology

About Power-X

Power (Qingdao) Energy Technology Co., Ltd. is located in Huai’an City, Jiangsu Province, China, mainly R&D and manufacture lithium-ion battery for residential energy storage systems and small industrial and commercial energy storage systems. The mission of Power (Qingdao) Energy Technology Co., Ltd. is to make the customer worry-free. The company’s proprietary advanced battery management system (BMS) and its self-developed patented technology has passed TUV, IEC, CE, Australian, New Zealand, Japan, the US, the UK, Southeast Asia, the Middle East, and other countries and regions. Power (Qingdao) Energy Technology Co., Ltd. energy storage battery brings customers great using experience.

The company’s production base covers an area of about 23,585 square meters, and the R&D building covers an area of about 11,000 square meters. The factory is equipped with 2 modern production lines of lithium-ion battery energy storage systems while greatly improving production efficiency. At present, annual production capacity of the factory can reach 1.5GWH lithium battery energy storage system.

20+R&D TEAM

R&D team more than 20 members. Total acquisition 50+ patented technology

15 Years+ Experience

Power-X has been in soalr energy for over 15 years, provides an overall solution for obtaining and storing light energy applications.

100+Countries&Regions

We have extensive export experience and offer reliable products to customers worldwide.

63,000 Square Meters

63,000 square meters of production area, daily capacity of 3 megawatts, 182-210mm compatible

Quality measurement system

Product Design

The established design models for optics, electricity, mechanics, and heat integrate theory with experimental results and historical experience. A thorough analysis of product value is conducted based on the application scenarios.

Material Select

Tailor the measurement process to suit the distinctive features of the material. Give preference to suppliers with sound financial standing. Rigorous testing procedures have been carried out on components composed of new materials to ensure their dependability.

Product Planning

Achieving a high degree of consistency and widespread applicability of materials is vital through both product and material standardization measures.

Relliability testing

Our enterprise laboratory is highly advanced and acknowledged by prominent third-party institutions. Our product goes through rigorous internal reliability testing, ensuring its quality and reliability. Furthermore, the product exhibits exceptional performance in the enhanced testing conducted by third-party organizations.

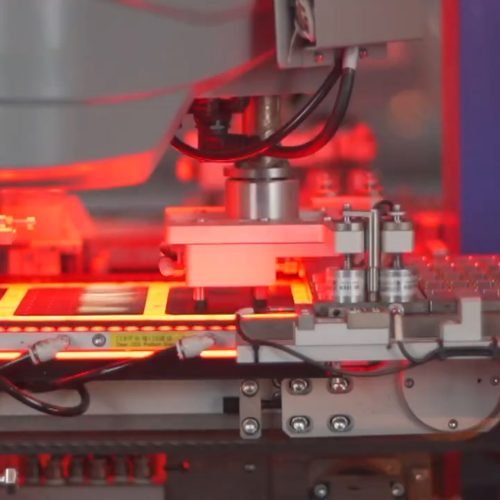

Production and Manufacture

Measures are implemented to ensure the excellence of highly automated production lines. These measures are carefully designed to maintain the highest standards of quality throughout the production process.

Demonstration of outdoor power generation

For optimal power generation performance, a comprehensive approach that integrates theoretical analysis, practical demonstration, and reliability assessment is recommended. Collaborating with trusted third-party institutions and clients for joint demonstration can increase the verification process's credibility and effectiveness.

Intelligent manufacturing

Power-X uses a flexible, intelligent production mode that incorporates automation and intelligence for a yield of up to 99.3%. This process leverages big data to make production transparent and traceable, allowing for access to component data at any time for timely, efficient, and stable component delivery to customers.

AI Product Testing

4*EL Test

Power-X production process employs 4x EL detection with horizontal direct illumination and equipment identification accuracy of <0.5mm/pixel. The process takes 2s per string and includes an AI intelligent judgment function for detecting defect types and equipment performance.